Polypropylene Tanks

Polypropylene tanks are all-purpose containers made from a typical thermoplastic polymer and are included in the broad category of plastic or poly tanks. Storage tanks can be built from various plastics, including polypropylene (PP). However, this specific polymer’s characteristics include specific benefits like outstanding chemical and corrosion resistance and a high melting point of 320° F. Read More…

Roto Dynamics Inc., custom rotational molders serving rotomolding and plastic tank needs nationwide. We are dedicated to our customers manufacturing needs. Building customer relationships based on integrity and communication assists us in developing a competitive advantage within the industry.

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

Specializing in fabricated plastic tanks such as water tanks, polypropylene tanks, polyethylene tanks and storage tanks, Park Plastic Products is capable of making your plastic tank in any size or dimension.

Sherman Roto Tank specializes in tanks that are manufactured to be suitable to store and process chemicals. Our tanks are a great choice for any industry. All our products go through extensive testing in order to surpass the industry standards. We offer sizes varying from 65 gallon to 800 gallon tanks. Along with tanks we manufacture customizable stands.

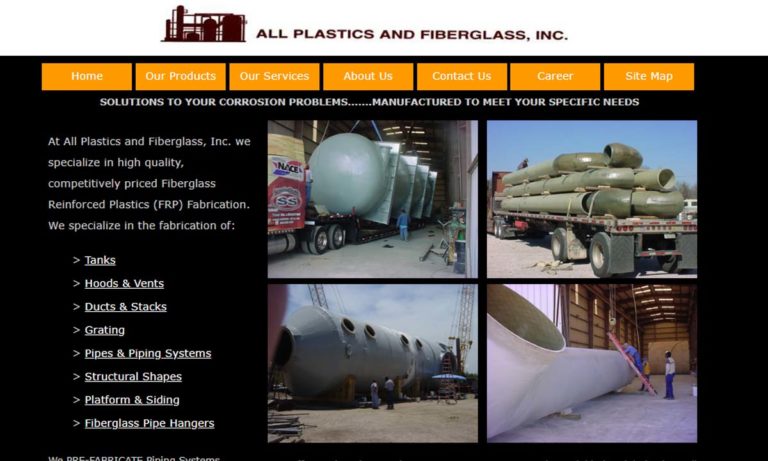

With over 100 years combined experience, All Plastics and Fiberglass has the experience to handle all your plastic and fiberglass needs.

Plas-Tanks Industries fabricates fiberglass-reinforced plastic tanks, chemical tanks (for storage) and vacuum vessels for storage, processing and mixing of water, wastewater and corrosive materials. We specialize in repairs, shop design and fabrication plus shop-built and field-assembled vessels.

Polyfab offers a diversified range of products & capabilities. Our highly skilled tank specialists fabricate plastic tanks of Polypropylene, PVC, Polyethylene, CPVC and Kynar. They also work with Stainless Steel & Mild Steel and design & build plating lines. Bulk Storage Tanks, Mixers, Plating Barrels, etc.

More Polypropylene Tank Manufacturers

The Manufacturing Process of Polypropylene Tanks

Unlike metal tanks, polypropylene tanks are easy to install and may be easily shaped to fit tank compartments. Injection molding is one typical technique for creating polypropylene tanks. We examine this process in greater detail below.

- The first step is to pour plastic polymer powder into the mold. The amount of powder needed will vary depending on the size of the finished tank and the desired wall thickness. The tank mold is then placed inside a sizable plastic water tank oven, which starts to apply heat. The heat gradually melts the polymer inside as the mold is progressively turned into a multi-axis pattern. As the mold is heated and rotated, the melted plastic "coats" the interior. Computer-controlled rotational angle and speed ensure that the desired wall thickness is reached even at various locations on the tank. Typically, the tank's bottom, where the highest pressure will exist, is where the wall is thickest. Depending on the tank size, the mold will rotate in the oven between one and three hours. Plastic storage tanks may have "seam lines." These lines are caused by separation lines between the mold's two sections rather than seams. A tank mold has a top and bottom piece that can extract a finished tank from the mold. The combined mold's top and bottom walls are offset since the top is fastened to the bottom.

- The chilling phase is the second step. The mold continues to rotate (often at a different speed and angle) while heat is removed. The plastic solidifies against the mold's interior during this period. Normally, this process takes under an hour. The cooling rate will be maintained within a specific range to produce a product with a smooth surface rather than a deformed one. The temperature must be decreased until the substance has solidified and an operator can securely remove the tank from the mold.

- The third step is to take the tank out of the mold. Larger tanks require the assistance of a forklift or other big machinery, whereas smaller tanks are frequently removable by hand. One enormous hollow piece of plastic the size of the storage tank is gently removed from the mold. The tank is then relocated to a location where a passageway assembly and pipe fittings will be installed.

The polypropylene tank is then kept under intense pressure in the mold until it freezes and can be removed.

Advantages of Polypropylene Tanks

Although it is significantly stronger than polyethylene and has a higher melting point, polypropylene is less frequently utilized for tanks than polyethylene. Polypropylene's crystalline structure is between low-density polyethylene (LDPE) and high-density polyethylene (HDPE).

Polypropylene tanks provide several advantages over conventional metal tanks made of steel, stainless steel, and titanium. These benefits include improved impact strength and resistance to rust, corrosion, chemicals, and gasoline additives thanks to the seamless design of the tanks. These practically unbreakable tanks also last longer than metal tanks, which are more likely to fracture and leak.

Disadvantages of Polypropylene Tanks

- Due to its frequent UV deterioration, polypropylene is not recommended for usage at high altitudes or in areas with intense UV rays.

- Since polypropylene suffers from chain degradation, which might result in oxidation, its use in high temperatures is restricted. This degradation causes the polypropylene to break. However, polymer stabilizers can repair this.

- Because of its weak bonding abilities, polypropylene is a challenging material to paint. Treating the surface to increase the adhesion of paints and inks that can color polypropylene is one way to fix this.

- Polypropylene melts when heated and is extremely explosive.

Life Expectancy of Polypropylene Tanks

The chemical being held and the tank's operational conditions are the first and most evident factors of a polypropylene tank’s life expectancy. Chemicals that are highly caustic, acidic, or stress-cracking are difficult on polypropylene tanks. Chemicals may permeate or dry out the plastic depending on the substance, tank design, and actual processing of the resin. Life expectancy is also significantly influenced by operating temperature. The way the chemical reacts with the plastic is affected by higher temperatures.

Choosing the Correct Polypropylene Tank Manufacturer

To ensure you have the most beneficial outcome when purchasing polypropylene tanks from a polypropylene tank manufacturer, it is important to compare several companies using our directory of polypropylene tank manufacturers. Each polypropylene tank manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each polypropylene tank business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple polypropylene tank companies with the same form.

55 Gallon Drums

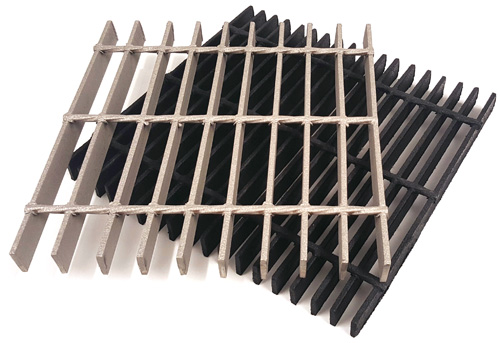

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services