Plastic tanks can be defined as containment vessels that are designed to store different kinds of substances. They are also commonly known as poly tanks, and are used in a variety of industrial applications. Read More…

Roto Dynamics Inc., custom rotational molders serving rotomolding and plastic tank needs nationwide. We are dedicated to our customers manufacturing needs. Building customer relationships based on integrity and communication assists us in developing a competitive advantage within the industry.

With over 100 years combined experience, All Plastics and Fiberglass has the experience to handle all your plastic and fiberglass needs.

Specializing in fabricated plastic tanks such as water tanks, polypropylene tanks, polyethylene tanks and storage tanks, Park Plastic Products is capable of making your plastic tank in any size or dimension.

Sherman Roto Tank specializes in tanks that are manufactured to be suitable to store and process chemicals. Our tanks are a great choice for any industry. All our products go through extensive testing in order to surpass the industry standards. We offer sizes varying from 65 gallon to 800 gallon tanks. Along with tanks we manufacture customizable stands.

Plas-Tanks Industries fabricates fiberglass-reinforced plastic tanks, chemical tanks (for storage) and vacuum vessels for storage, processing and mixing of water, wastewater and corrosive materials. We specialize in repairs, shop design and fabrication plus shop-built and field-assembled vessels.

Polyfab offers a diversified range of products & capabilities. Our highly skilled tank specialists fabricate plastic tanks of Polypropylene, PVC, Polyethylene, CPVC and Kynar. They also work with Stainless Steel & Mild Steel and design & build plating lines. Bulk Storage Tanks, Mixers, Plating Barrels, etc.

More Plastic Tank Manufacturers

Applications

Plastic tanks serve a multitude of purposes in material storage and transportation across various industries. In agriculture, they are integral to irrigation and fertilization systems. In the petrochemical sector, plastic tanks facilitate the transportation and storage of oil and gas.

These versatile tanks find applications in numerous fields, including gas and oil, agriculture, water treatment, chemicals, food and beverage, recycling, industrial parts washing, manufacturing, and electroplating.

The History of Plastic Tanks

For millennia, humans have relied on tanks crafted from materials like stone, ceramic, and wood. The Indus Valley Civilization, flourishing from 3000 to 1500 BC, employed tanks to store water and grain. Similarly, medieval Europeans fortified their castles with water tanks as provisions during sieges.

Plastic tanks emerged significantly only from the mid-20th century onwards. While plastic was synthesized from the 1800s, it couldn’t be effectively utilized for tank production until advancements in technology occurred. The breakthrough arrived in the 1960s with the development of rotational plastic molding, enabling manufacturers to create large hollow containers initially using low-density polyethylene. Over the past five decades, continuous advancements by engineers and chemists have refined processes and introduced new plastic compounds. This ongoing innovation has fostered growth and diversification within the plastic tank industry.

Plastic tank manufacturers and suppliers are increasingly focusing on sustainability. While plastic tanks are recyclable, the industry continues to explore ways to reduce their environmental footprint and contribute to a healthier planet.

Design

Production

Plastic tanks are crafted using either rotary molding or plastic injection molding techniques. The process starts with manufacturing a stainless steel canister-shaped mold, which is digitally designed beforehand. Next, the mold is filled with plastic granules or powder, sealed, and rotated over a heat source to melt the plastic material into the mold’s shape. Afterward, the plastic is left to cool and solidify. Once the cooling is complete, the canister is opened to unveil the formed tank inside. To adjust the thickness of the tank walls, manufacturers simply vary the amount of plastic material used.

Materials

Plastic tanks are typically made from materials such as polyethylene (PE), polypropylene (PP), and fiberglass reinforced plastic (FRP). Varieties of polyethylene used include high density polyethylene (HDPE), low density polyethylene (LDPE), medium density polyethylene (MDPE), linear low-density polyethylene (LLDPE), and cross-linked polyethylene (XLPE). Additional plastics like polyvinyl chloride (PVC) or polyvinylidene chloride (PVDF) may also be utilized in their fabrication.

Different plastic types vary in their common qualities such as corrosion resistance, impact resistance, sterility, durability, chemical resistance, and hardness. Manufacturers select the appropriate plastic tank material based on specific application needs.

Customization

If you can’t find the tank you need on the standard market, opting for custom manufacturing might be your best bet. Custom plastic tanks come in a variety of configurations, orientations (horizontal or vertical), colors, shapes, and sizes to suit your specific needs. Manufacturers can even incorporate translucent walls, allowing for easy monitoring of tank contents. Plastic tanks are available in sizes ranging from 15 gallons to 16,000 gallons, ensuring they meet diverse capacity requirements.

Types

Plastic tanks can be categorized in several ways, with three primary methods being most common:

- Based on the material they contain.

- According to the type of material used in their fabrication.

- Considering their application and design.

Various types of plastic tanks are categorized based on the substances they store. These include water tanks, plastic fuel tanks, chemical tanks, and plastic oil tanks. Examples of tanks categorized by their material composition include polyethylene tanks, polypropylene tanks, and FRP tanks. Additionally, common examples in the third category comprise septic tanks, storage tanks, double wall tanks, and cone bottom tanks.

Water Tank

The water tank serves a specific purpose: storing water for various applications such as household drinking and fire extinguishing. Plastic water tanks can be made from several materials, with PE being the most prevalent. PP, PVC, and PVDF are also options for fabrication. PE is favored due to its lightweight properties and resistance to chemicals. Water tanks intended for human consumption must meet food-grade standards.

Plastic Fuel Tank

Plastic fuel tanks serve dual roles in transporting and storing flammable substances while gauging substance levels in the engine, proving indispensable for anticipating potentially hazardous situations. They are typically crafted from five primary materials: high-density polyethylene (HDPE), PP, recycled polyethylene (regrind plastic), and a plastic adhesive or ethyl vinyl alcohol (EVOH).

Chemical Tank

Chemical tanks store aggressive or highly reactive chemicals, like sulphuric acid. Manufacturers of plastic tanks construct these chemical storage tanks with interiors and fittings designed to resist reactions and corrosion.

Plastic Oil Tank

Plastic oil tanks resemble plastic fuel tanks, but they are crafted from distinct materials. Manufacturers typically use fiberglass reinforced plastic (also known as glass reinforced plastic or FRP) and molded polyethylene to fabricate them.

Polyethylene Tank

Polyethylene tanks exhibit versatility, serving non-pressure storage needs for a wide array of liquids, chemicals, and solids such as alkalis, acids, water, and solvents. These tanks are fortified with UV treatment for exceptional durability and are food grade approved, ensuring suitability for storing water.

Polypropylene Tank

Polypropylene tanks boast resistance to heat (with a melting point of 320℉), moisture, chemicals, and corrosive materials. They are known for their durability, lightweight nature, and rigidity. These qualities make them particularly favored in stainless steel processing plants.

FRP Tank (GRP Tank)

FRP tanks, primarily composed of glass-reinforced plastic (GRP), are widely employed in food processing due to their FDA approval.

Septic Tank

Septic tanks serve a highly specialized role, designed specifically to contain substances integral to sewage treatment processes. A plastic septic tank system comprises two fundamental components: the septic tank and a drain field, working in tandem to form an on-site sewage treatment system.

Storage Tank

Plastic storage tanks serve the basic function of storing various materials. This versatile application finds use across nearly every industry, showcasing its broad utility. Consequently, these tanks come in a myriad of configurations tailored to different needs.

Double Wall Tank

Double-wall tanks are characterized by an outer layer fortified with an additional plastic coating, from which the tank derives its name. This supplementary plastic layer enhances safety by effectively averting leaks during material storage, transportation, and rigorous processing. Hence, double-wall tanks are employed for the containment of hazardous waste and other substances that pose potential risks.

Cone Bottom Tank

Cone bottom tanks derive their name from their tapered, conical bottom end. They aim to achieve two main objectives: 1) streamline the dispensing process from the tank’s base, and 2) enhance the efficiency of draining the tank.

Advantages of Plastic Tanks

There are numerous advantages to opting for plastic tanks over other alternatives. Firstly, plastic is less prone to react with the contents compared to materials like metals. This quality is crucial when storing aggressive chemicals such as caustics and acids, commonly used in industrial chemical applications. Secondly, most plastic tanks can either be recycled or repurposed; for instance, old plastic tanks can find new life as outdoor trash bins or barriers. Thirdly, plastic tanks offer versatility in design and various functional possibilities. Lastly, they are manufactured with precision, uniformity, and strength.

Accessories

Depending on the type of tank and its intended use, investing in accessories can greatly enhance functionality. Consider purchasing fittings to adapt the tank to its new role. Valves are essential for regulating water flow in storage applications, while hoses are necessary for draining or feeding purposes. Other useful accessories include tie-down kits, pumps, rainwater collection adaptors, lids or manways, precision gauges, siphon tubes, strainer baskets, restraints, and float valves.

Installation

Tank installation procedures vary by the details of the installation site, such as whether it is above or below ground. They also vary by application. For example, do you require easy access to the contents? That impacts where you place your tank.

A fundamental requirement for installation is ensuring the tank is securely positioned. It’s crucial to utilize appropriate tools to prevent any damage. Your tank should include detailed installation instructions. For expert guidance, consulting your supplier is highly recommended for comprehensive advice.

Proper Care for Plastic Tanks

Here are a couple of tips to ensure plastic tanks endure over time if cared for properly.

- Always ensure the tank is supported from the bottom when handling.

- Make sure to always install or mount the tank on a stable surface capable of handling the pressure to prevent the risk of it tipping over and rupturing.

- Ensure materials prone to falling are kept away from the tank.

- Avoid exposing your tank to extreme temperatures, whether excessively hot (including hot water) or excessively cold.

- Similarly, avoid placing your tank in environments that it isn’t designed to handle.

- Avoid storing tanks containing flammable liquids near any open flames.

- Regularly clean the tanks after each use.

Standards

Your plastic tank must meet specific standards tailored to your application, industry, and location. In the United States, for instance, tanks intended for petroleum storage must conform to the American Petroleum Institute (API) standards. Similarly, tanks holding flammable liquids should comply with guidelines from the National Fire Protection Association (NFPA). Other essential standards are established by organizations such as Underwriters Laboratories (UL), the American National Standards Institute (ANSI), the American Society of Mechanical Engineers (ASME), and the American Society for Testing and Materials (ASTM). These standards serve as critical benchmarks used across governmental regulations and various industries.

Selecting a Manufacturer

Before committing to collaborate with any supplier or manufacturer, ensure they can meet your specifications and uphold a reputation for outstanding customer service. For reliable manufacturers, explore the companies featured on this page. Each partner we endorse has demonstrated expertise in their field. Dive deeper into their profiles and visit their respective websites to learn more about them.

Check out our Plastic Tubing website

Check out our Rotational Molding website

55 Gallon Drums

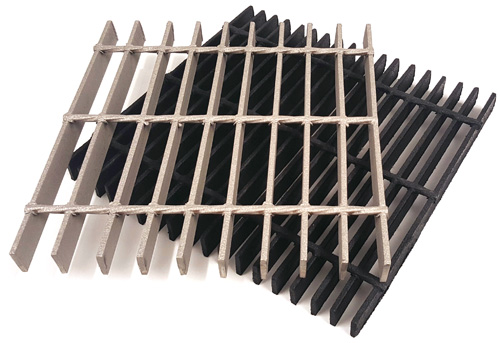

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services