Plastic oil tanks are often used in applications such as domestic central heating systems, on trucks and trains for oil transportation, in gas stations, and any building that uses oil to fuel their heating systems. Read More…

Roto Dynamics Inc., custom rotational molders serving rotomolding and plastic tank needs nationwide. We are dedicated to our customers manufacturing needs. Building customer relationships based on integrity and communication assists us in developing a competitive advantage within the industry.

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

Specializing in fabricated plastic tanks such as water tanks, polypropylene tanks, polyethylene tanks and storage tanks, Park Plastic Products is capable of making your plastic tank in any size or dimension.

Sherman Roto Tank specializes in tanks that are manufactured to be suitable to store and process chemicals. Our tanks are a great choice for any industry. All our products go through extensive testing in order to surpass the industry standards. We offer sizes varying from 65 gallon to 800 gallon tanks. Along with tanks we manufacture customizable stands.

With over 100 years combined experience, All Plastics and Fiberglass has the experience to handle all your plastic and fiberglass needs.

Plas-Tanks Industries fabricates fiberglass-reinforced plastic tanks, chemical tanks (for storage) and vacuum vessels for storage, processing and mixing of water, wastewater and corrosive materials. We specialize in repairs, shop design and fabrication plus shop-built and field-assembled vessels.

Polyfab offers a diversified range of products & capabilities. Our highly skilled tank specialists fabricate plastic tanks of Polypropylene, PVC, Polyethylene, CPVC and Kynar. They also work with Stainless Steel & Mild Steel and design & build plating lines. Bulk Storage Tanks, Mixers, Plating Barrels, etc.

More Plastic Oil Tank Manufacturers

Plastic oil tanks can be used in either above ground or underground oil storage applications, but are most commonly used in underground. One example of an above ground storage application for plastic oil tanks is the storage of heating oil for residential purposes. An example of an underground storage tank for plastic oil tanks is for the storage of heating oil for industrial or commercial purposes as well as the storage of various fuel types such as motor oils, diesel duel, fuel oil for automotive applications.

Plastic materials are a popular alternative to metals like stainless steel for manufacturing oil tanks; however, plastic oil tanks are not recommended for use in the storage of certain aggressive chemicals such as strong oxidizers, aromatics, gasoline or jet fuel.

Plastic oil tanks are made a couple of different ways, but their most common processes are injection molding and contact molding. Injection molding is utilized for plastic oil tanks fabricated from polyethylene, while contact molding is for plastic oil tanks formed from FRP. Injection molding functions by first heating plastic pellets and then injecting the molten plastic material into the cavity of a split die chamber/mold, which is then clamped shut.

The plastic resin cools as water or other fluids circulate through the cooling system of the mold, extracting the heat and solidifying the tank. Contact molding, on the other hand, applies many different layers to a large round mold. They are all measured in gallons and can hold anywhere from 5 to 13,000 gallons apiece.

Depending on their size and the desired wall strength, oil tanks are composed of either one or two layers. They can stand alone or be integrally bundled, which means multiple tanks are attached to one another by a system of plastic internally-coated copper piping. Every plastic oil tank, whether above ground, underground, horizontal or vertical, has vents, a content gauge, an isolation valve and an overfill alarm for safety reasons.

55 Gallon Drums

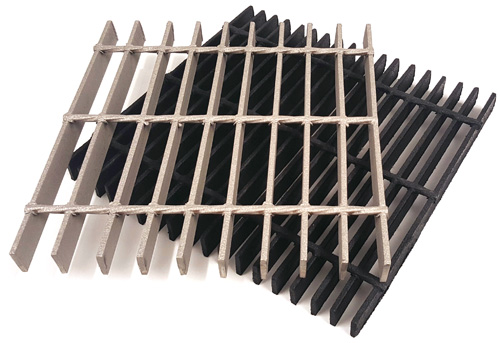

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services